Food Grade Conveyor Systems Ohio

Move Food Efficiently & Safely

The Food and Drug Administration (FDA) closely monitors processing operations for plants that move food and pharmaceuticals.

Capital City Conveyor and Supply has the food grade sanitary conveyors and systems that are critical to getting food from farm to table.

Over 60 Years

Fast & Reliable

One-Stop-Shop

The Slightest Contamination Can Shut Down an Entire Plant

Because of strict and necessary FDA requirements, any food processing environment requires a food-safe conveyor system. The slightest contamination can shut down your entire processing plant!

We understand the safety implications, FDA regulations, and the conveyor equipment you need for proper compliance.

With over 60 years of combined experience with conveyor systems that service all industries, including the food and pharmaceutical industries, we can design a food-safe conveyor system that meets all the safety, hazard and sanitation requirements your plant could face.

Our food grade conveyor systems are designed for:

Start by choosing the best system for your food handling needs.

What Are The Different Types of Food Conveyors?

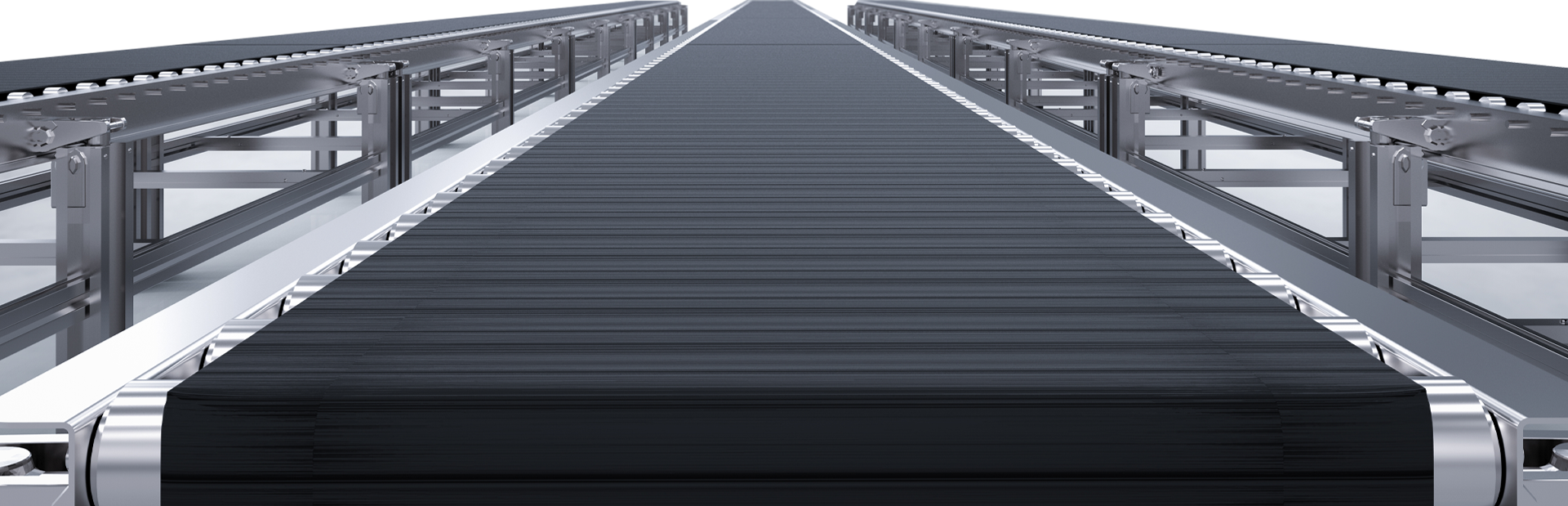

There are two types of food conveyors: metal and plastic. Despite the material, each uses sanitary conveyor belts. All areas of the belt are accessible to clean, which is a must for food handling.

Metal Food Conveyor Belts

If any coating is necessary, metal belts can be a great conveying solution because of their draining capabilities. For example, a metal conveyor transporting produce from the field through a washer allows the water to easily drain from the belt.

Powered Roller Conveyor

Three Simple Steps to Take the Guesswork out of Your Conveyor System Needs

Contact us to Order

Delivery

Make a Plan for Maintenance

Frequently Asked Questions

Which is Better For Food? Plastic vs. metal food belts

As long as the conveyor system uses a sanitary belt, both metal and plastic are great materials for food processing. Both have strengths and weaknesses depending on the processing stage. Metal belts are compatible with baking and cooking food. Plastic belts can withstand more impact when deboning and cutting up food.

How Often Should I Replace My Food Grade Conveyor Belts?

To ensure a food conveyor is always compliant, it is always safer to replace rather than repair. There are high risks that come with repairing a food processing conveyor. Malfunctioning equipment can hinder sanitation and result in unnecessary inspections, as well as product recalls. Keep production moving with your trusted conveyor replacement partners right here in Columbus, Ohio.

How can I find the right food industry conveyor system solutions?

The food industry has specific criteria to follow when it comes to handling products. Contact us today to learn about how our food-grade conveyor systems can speed up your production and maintain FDA compliance.