Flexible Conveyor Systems Ohio

Expand Your Operations with Flexible Conveyors

Flexibility is just the beginning. These conveyors are also expandable, portable, extremely efficient and can be added to existing conveyor systems.

Flexible conveyors, sometimes referred to as expandable conveyors, are an essential investment for your thriving manufacturing, shipping, and receiving operation.

Over 60 Years

Of combined experience with conveyors

Fast & Reliable

Network of Vendors

One-Stop-Shop

For Custom Conveyor Solutions & Parts

Shipping volume is up. Can your conveyors handle it?

In 2020, global shipping volume hit an all-time high of 131 billion parcels. That number is expected to reach approximately 266 billion by the year 2026. If your conveyor system doesn’t have the flexibility and expandability to keep up, you’ll be left behind.

Increased shipping should mean increased opportunity and revenue for your business. But that won’t happen without the right flexible conveyor system.

What can I use flexible conveyors for?

Flexible conveyors can serve a range of functions and are ideally suited at loading docks, retail back rooms, and high-traffic shipping areas. Any loading and unloading procedures can benefit from the multi-functionality of flexible conveyors. Some businesses that benefit include:

Clothing Stores: Receiving shipments to retail back rooms becomes quick and painless

Restaurants: Less time spent unloading supply trucks

Distribution Centers: Using the same flexible conveyor at multiple docks keeps work momentum going

We can help expand your conveyor’s versatility and your company’s profitability.

Nearly all businesses become more versatile after implementing flexible conveyors into their materials handling operation, whether flexible gravity conveyors or powered flexible powered conveyors.

Flexible Gravity Conveyors provide an easy, portable assembly line using manual force and gravity to transport boxes, containers, and other flat-shaped items quickly and efficiently.

Powered Flexible Conveyors are powered by a small motor and have the ability to expand and contract making shipping and receiving, warehouses, distribution centers, and assembly lines move faster.

Specifications often determine the final cost. The longer and wider the conveyor design, the higher the price will be.

When comparing the costs of different flexible conveyors, consider the following questions:

How far will the product need to travel? What is the distance from load and/or unloading point to the destination?

What are the transported product’s dimensions? Will they fit on the conveyor?

How big is the spending budget?

By knowing this information ahead of time, it will be easier to find an affordable flexible conveyor design.

Discover How Flexible Conveyor Systems Can Help You

If you’re not sure where to start, contact us for a consultation. We listen to your needs and find gaps in any current conveying processes. We’ll pull together the best plan for your budget and focus on the big picture: moving product without sacrificing time, quality, or manpower.

Frequently Asked Questions

What are flexible conveyors?

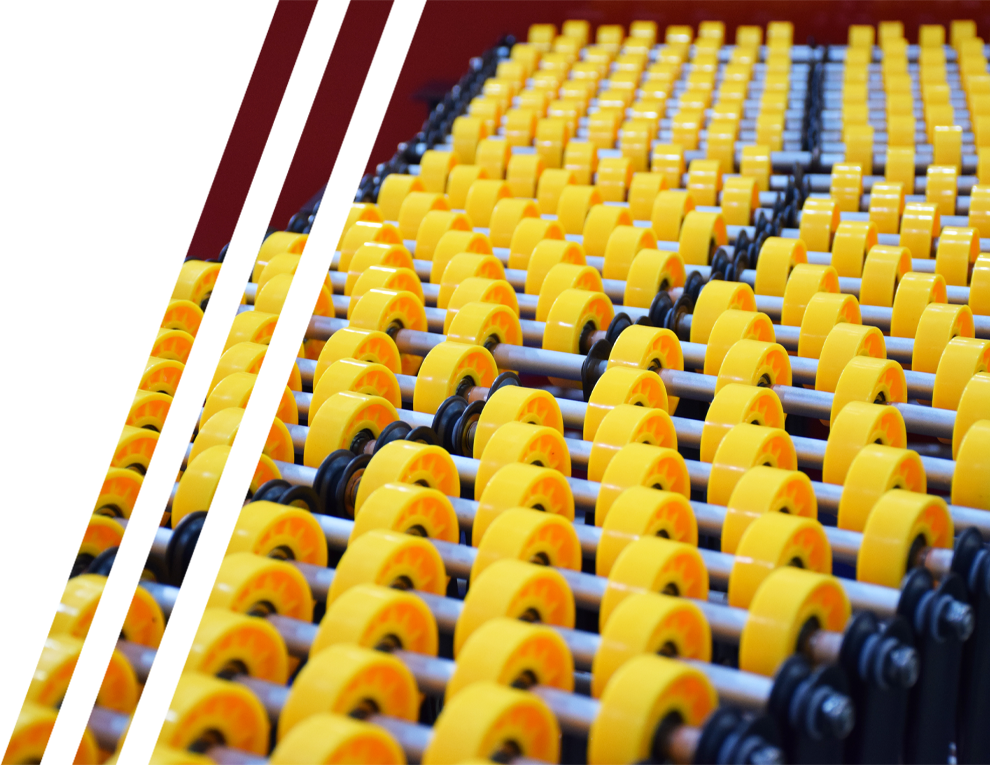

Flexible conveyors, sometimes called expandable conveyors, are flexible flat top chain conveyors and wheels.

Flexible conveyors allow any work environment to receive or distribute goods despite the layout. Special expanding and contracting features make both navigating corners and storage a seamless task. The system can expand into a single or curved line. When not in use, flexible conveyors can retract becoming small and compact so as to take up less floor space.

Flexible conveyors are also portable and can be moved from one location to another from plant floors and loading docks to assembly ports and storage rooms. They are also perfect as temporary conveyor lines.

Is there more than one type of flexible conveyor available? If so, how are they different from one another?

Yes, there are two types of flexible conveyors, flexible gravity conveyors and powered flexible conveyors.

Similar to traditional gravity roller designs, flexible gravity conveyors use manual force to move packages. They provide an easy, portable assembly line that uses the pull of gravity to transport boxes, containers, and other flat-shaped items.

Powered flexible conveyors use a small motor to move the belt at a steady pace. With expanding and contracting capabilities, shipping and receiving, warehouses, distribution centers, and assembly lines can move faster.

How can my company benefit from using flexible conveyors?

Nearly all businesses benefit from the adaptability of flexible conveyors. They make any loading and unloading, shipping and receiving, less labor intensive and time consuming. Because they can be more easily configured than traditional conveyors, they have better ergonomics. This can decrease worker fatigue and potential injury, and speed up production, packaging, shipping and receiving operations across various industries.

How do I choose the right flexible conveyor for my business?

If you’re not sure where to start, contact us at Capital City Conveyor and Supply for a consultation. We listen to your needs and find gaps in any current conveying processes. We’ll pull together the best plan for your budget and focus on the big picture: moving product without sacrificing time, quality, or manpower.