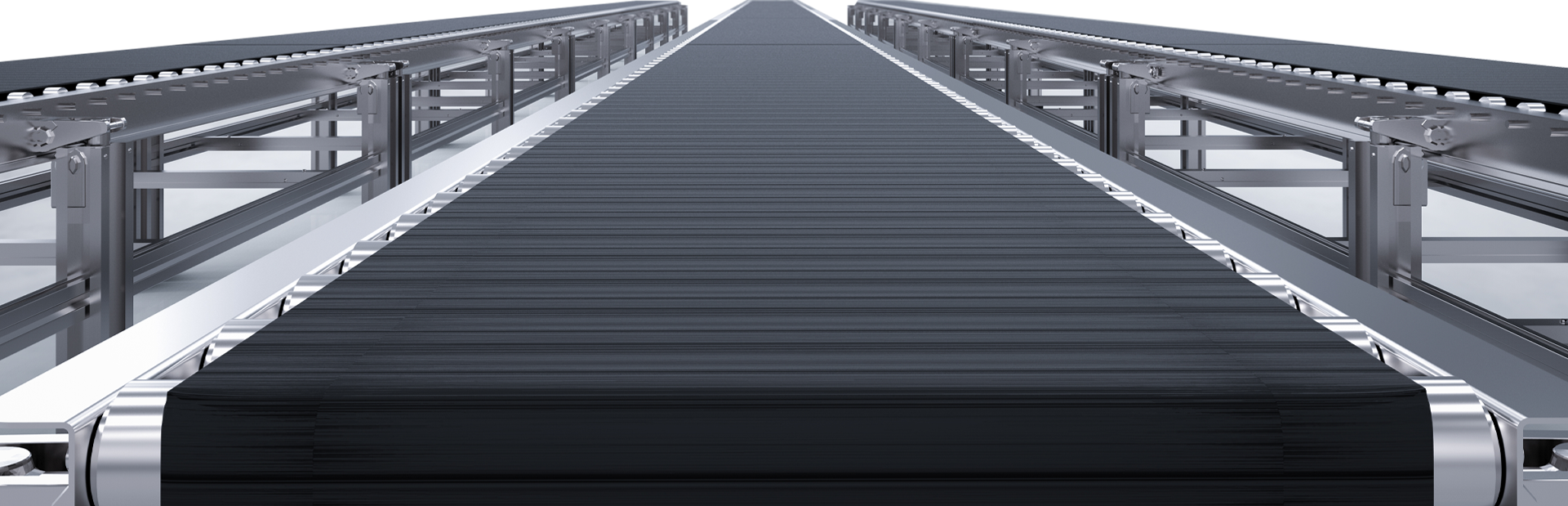

Chain conveyor Systems

Don’t Sacrifice Speed and Productivity Even with a Heavy Load

Chain conveyors carry the heaviest loads at a high speed, so you no longer have to sacrifice speed and productivity even with your largest materials handling jobs.

Over 60 Years

Fast & Reliable

One-Stop-Shop

Can your current conveyor system handle heavy-duty jobs with speed and efficiency?

Big jobs can take time. And without the right conveyor system, they can take lots of manpower too.

Don’t sacrifice efficiency and safety to keep your production line on track.

When moving large, heavy loads, worker safety is always of great concern. One mishap can send someone to the hospital, and can send your production line into chaos. Chain conveyor systems’ capacity to handle large, heavy loads is useful for industries like:

The Right Conveyor Chain for the Right Job

Plastic Conveyor Chain

Chain Disc Conveyor Designs

Drag Chain Conveyor Systems

Gain Competitive Edge with a Chain Conveyor

Contact for Pricing

Plan Your Solution

Finalize and Deliver

Frequently Asked Questions

Are chains lubricated in a drag conveyor?

Yes. Drag conveyors often use welded steel chains, which need routine lubrication to reduce wear. Performing routine maintenance like this will extend the drag conveyor’s lifespan.

Can Conveyor Chains Snap?

Yes. Chain failure can be categorized into three different groups.

- Tensile: This happens when the chain holds too much pressure. As a result, it stretches out and malfunctions.

- Fatigue: Using chain conveyor systems as intended, without extra pressures, can lead to fatigue. Over time, microscopic cracks develop on the link plates and side bars. These cracks get larger until the chain snaps.

- Wear: Friction between the pin and the bushing causes the chain to elongate and stretch out. It no longer grips the gears properly and causes the entire belt to malfunction.

Do Chains in Conveyors Need to Roll or Slide?

Conveyor chains can either roll or slide. Both are great mechanical options for a horizontal, straight route. When the chain slides, it rests on the edge of its plates. When rolling, the chain rests on the rollers. Particular uses will dictate implementation.